Expand Menu

0

My cart

৳0

Shopping cart

CloseYour cart is empty, and it looks like you haven’t added anything yet.

-

Categories

-

NS Series Kit

NS Series Kit

-

Arduino, ESP, Raspberry Pi ETC

Arduino, ESP, Raspberry Pi ETC

-

Arduino Accessories

Arduino Accessories

- Others

- Gyroscope And Accelerometer Sensor

- Recording Module

- Wheel

- Fingerprint Reader

- Car Chassis And Wheel

- Valve And Lock

- Converter

- Buzzer Module

- Rotary Encoder Module

- Bluetooth Module

- Timer Module

- Joy Stick And Key Pad Module

- Micro SD Card Module

- Relay Module

- nRF | GSM And GPS

- Digital Multiplexer

- Motor

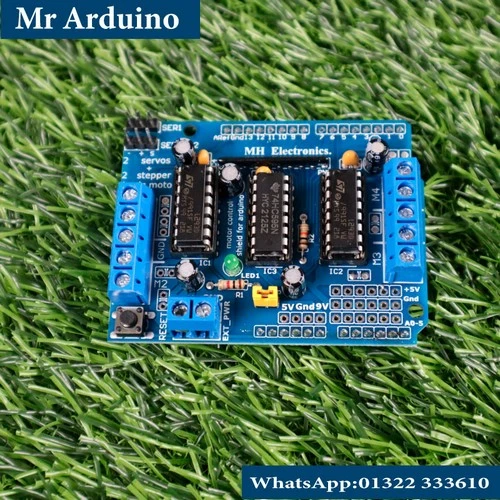

- Arduino Shield

- Display

-

Electronics Component

Electronics Component

-

Sensor & Sensor Module

Sensor & Sensor Module

-

Drone | Plane | RC Parts

Drone | Plane | RC Parts

-

Multimeter And Measurement

Multimeter And Measurement

-

Industrial Items

Industrial Items

-

IPS

IPS

-